UniTorq M-Series Actuators

A Tradition of Excellence

At UniTorq we understand the important role actuators play in the production process and how costly downtime can be. This is why we have prioritized providing products that meet the highest standards in engineering and quality. Our product line of pneumatic actuators is built to withstand the harshest environments and function reliably, reducing the risk of work stoppage.

UniTorq M-Series Actuators

Business demands more. Expectations increase, but one thing has always remained consistent…UniTorq’s continuous commitment to high quality standards, innovative design and product excellence.

Since 1991, UniTorq has consistently provided and developed reliable actuators and accessories. The new M-Series actuator was inspired by our on-going commitment to developing innovative products that keep up with the ever-changing industry needs that your business faces.

We have never been more proud to lead the way by developing our new M-Series line, which sets new standards in design, performance and reliability. Plus, by using local workers to assemble, paint and coat the product, we are redefining the very same excellence that you have always associated with our products.

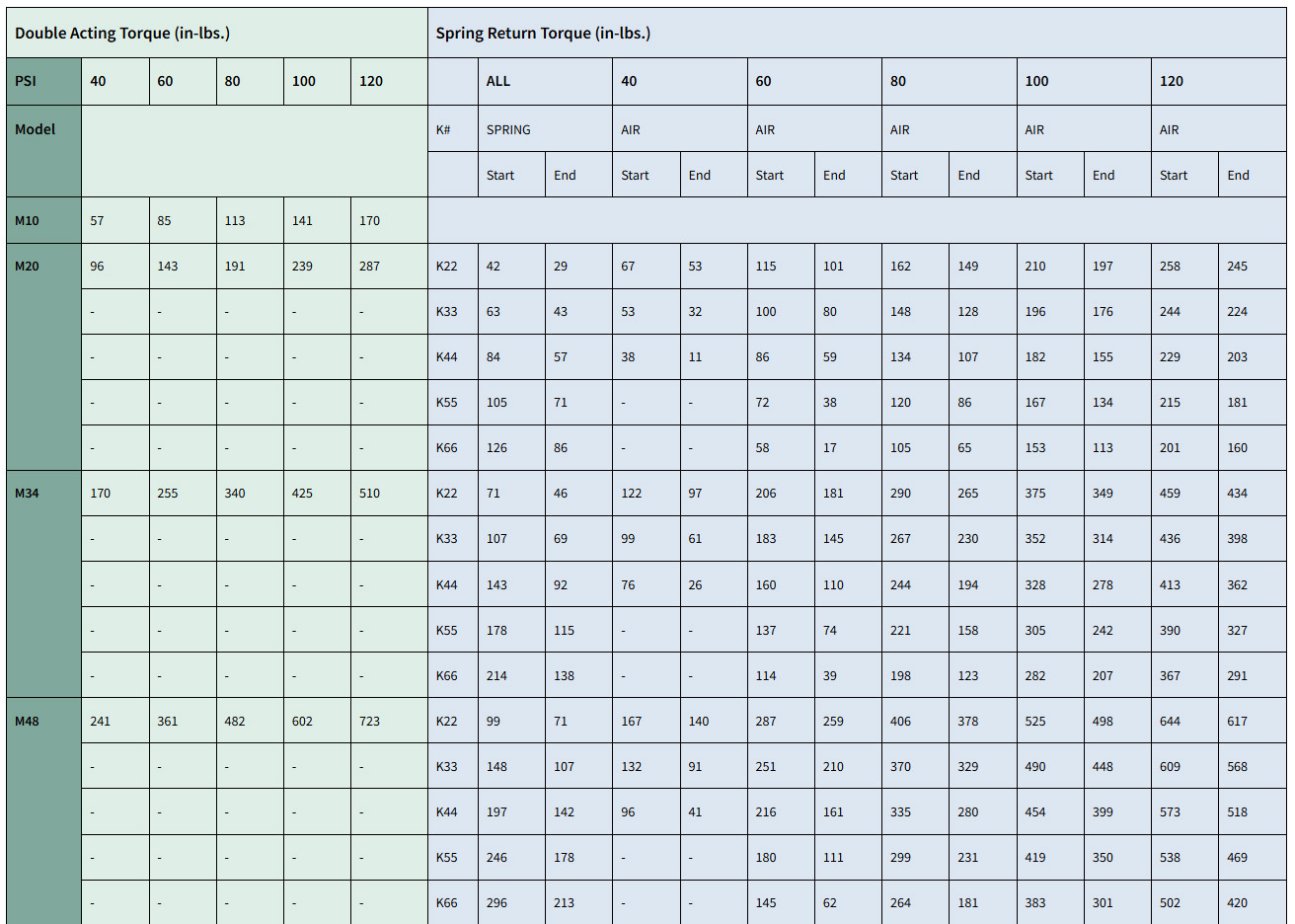

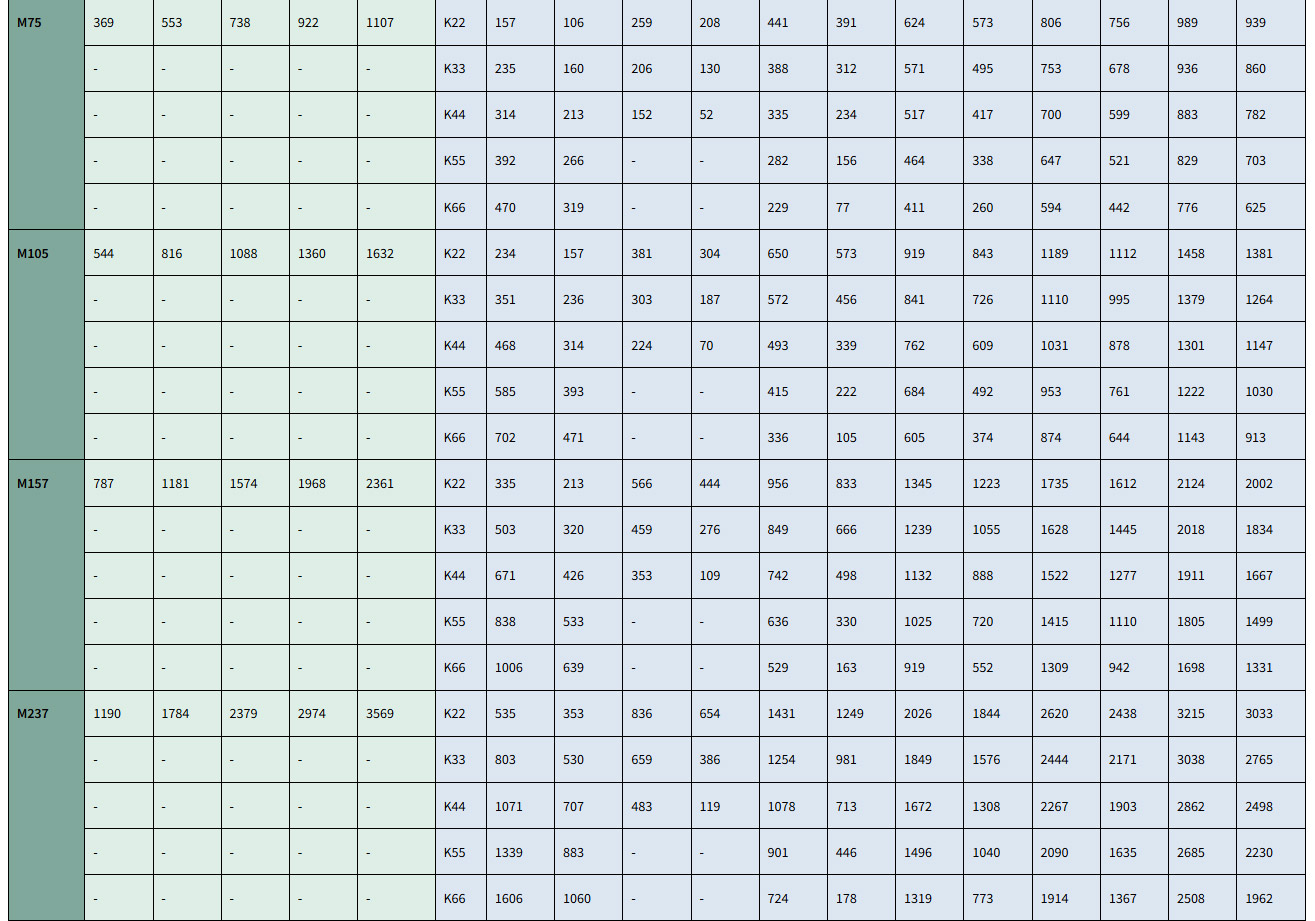

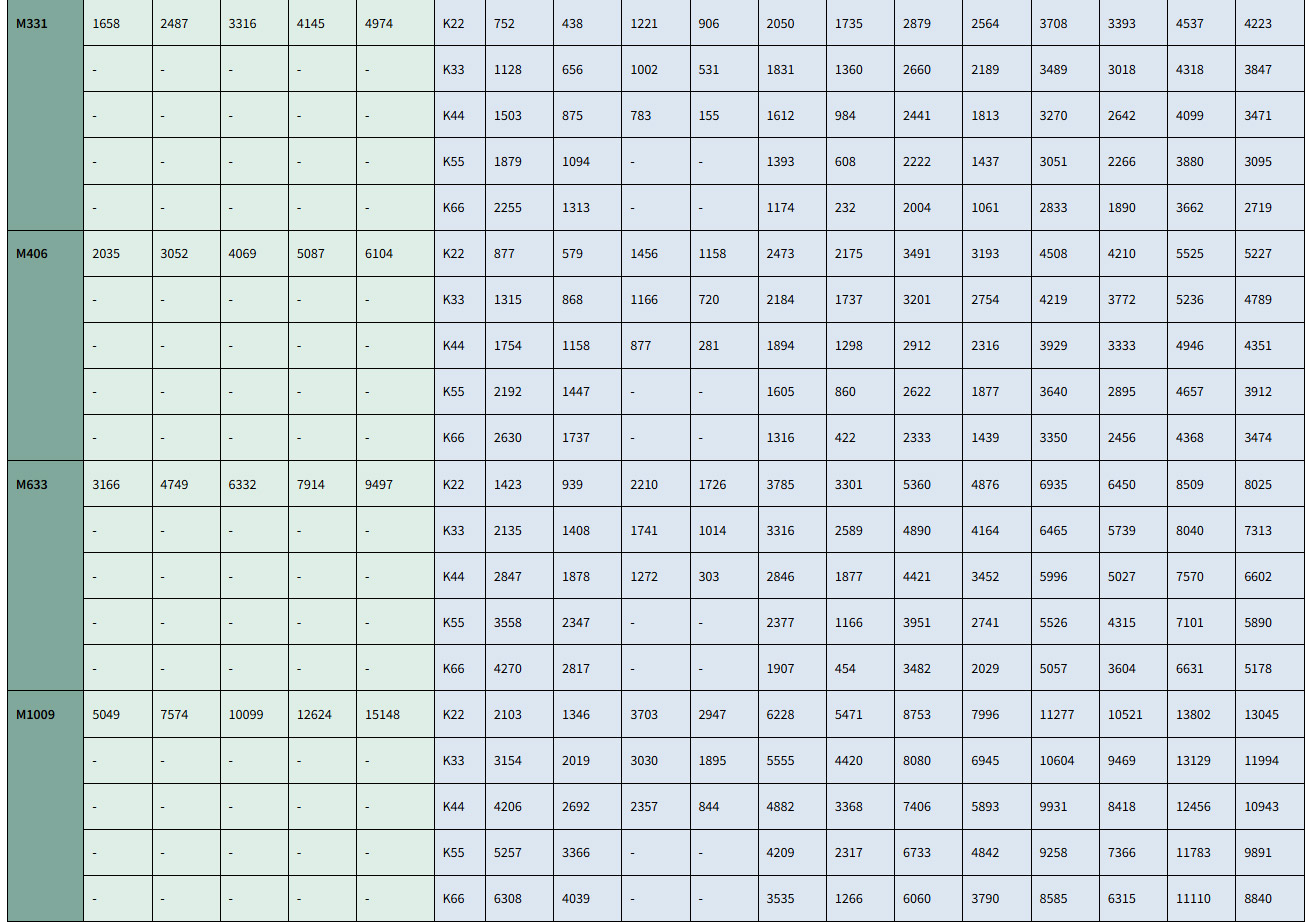

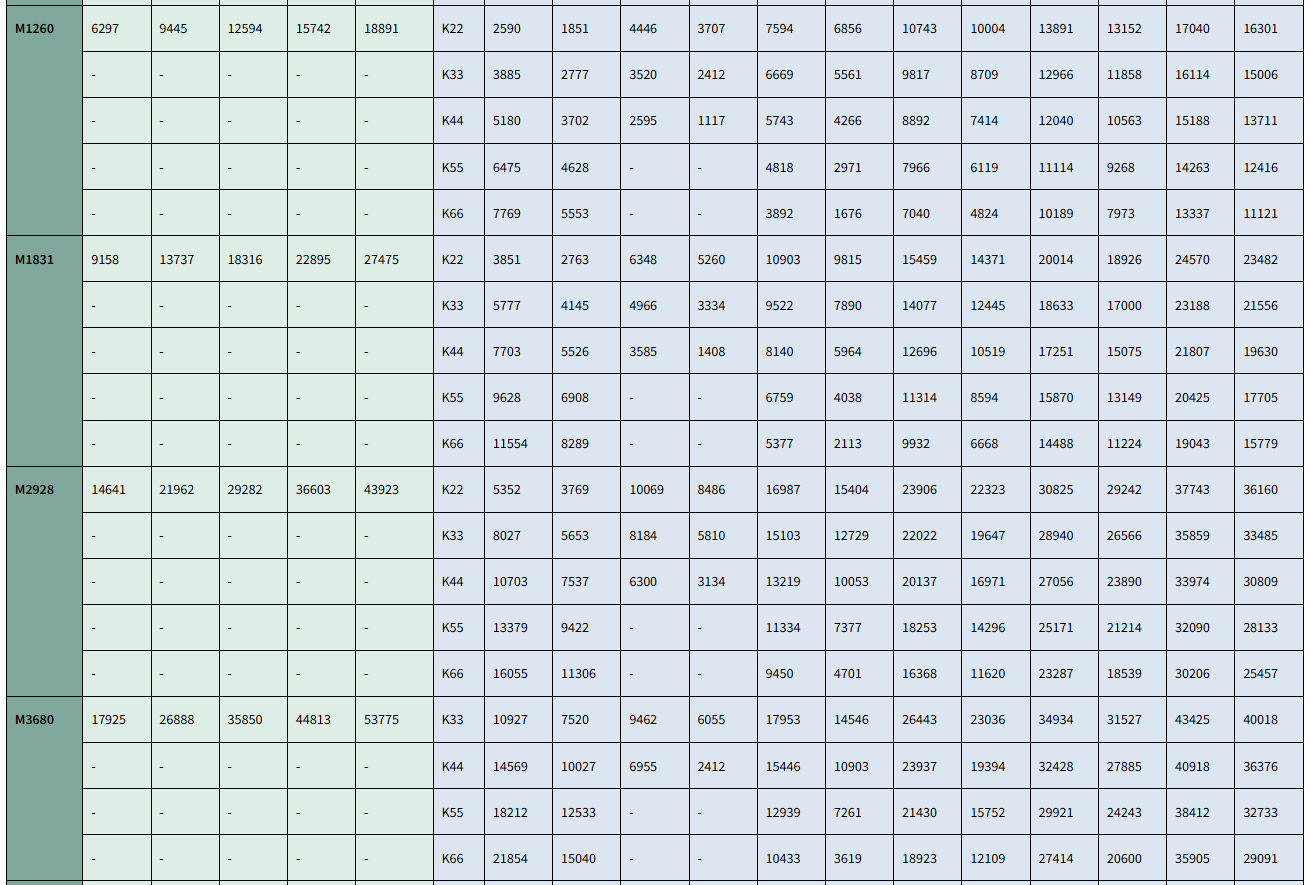

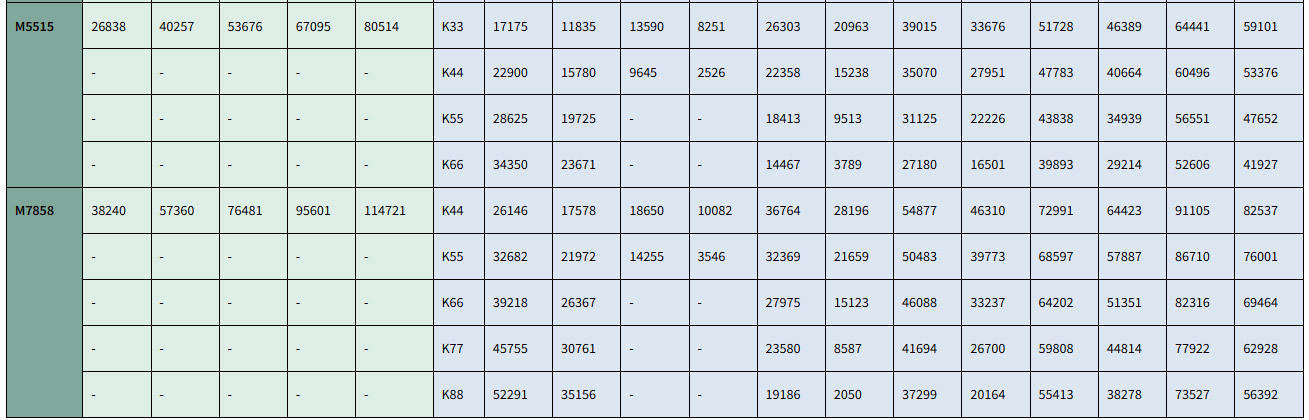

Speed/Torque Chart

M-Series Sizing Calculator

Specifications

Installation and Operation Manual (IOM)

Features

- Improved Travel Stop – Allows the actuator to stop off the pinion rather than the pistons.The standard actuator will have 100 degrees of travel with +5 or -5 degrees of adjustment on the open and close stop. The forged steel travel stop can be machined to any length of travel.

- New “Top Hat” Thrust Bearing Design – The thrust bearing provides the largest pinion bearing surface in the industry. This upgraded thrust bearing limits friction between the actuator body and pinion, increases durability by absorbing side-load forces, and extends the cycle life of pinion O-Rings.

- Increased Tooth Engagement – A minimum of two teeth are engaged at all times during the stroke for consistent torque output and accuracy.

Options

- Anodized type II

- Hard Anodized type III

- Anodized type II/epoxy polyester powder coat

- ANI (High Phosphorous Nickel Impregnated)

- Anodized type II or III/PTFE sealed

Available Options

- 120°, 135°, and 180° rotation in double acting and spring return

- Low and High temperature options

- Fast acting/quick exhaust

- 100% travel stop adjustment

- 3 position actuators

Mounting Options

- 3.25″ and 5″ bolt circles along with “Double D” and keyway pinions available for direct valve automation.

M-Series Sizing Calculator

Marketing Literature

Engineering Documents

The links below will provide a PDF document containing dimensional drawings, weights, mounting patterns, and sizes for that model.

M Series 120 Actuator