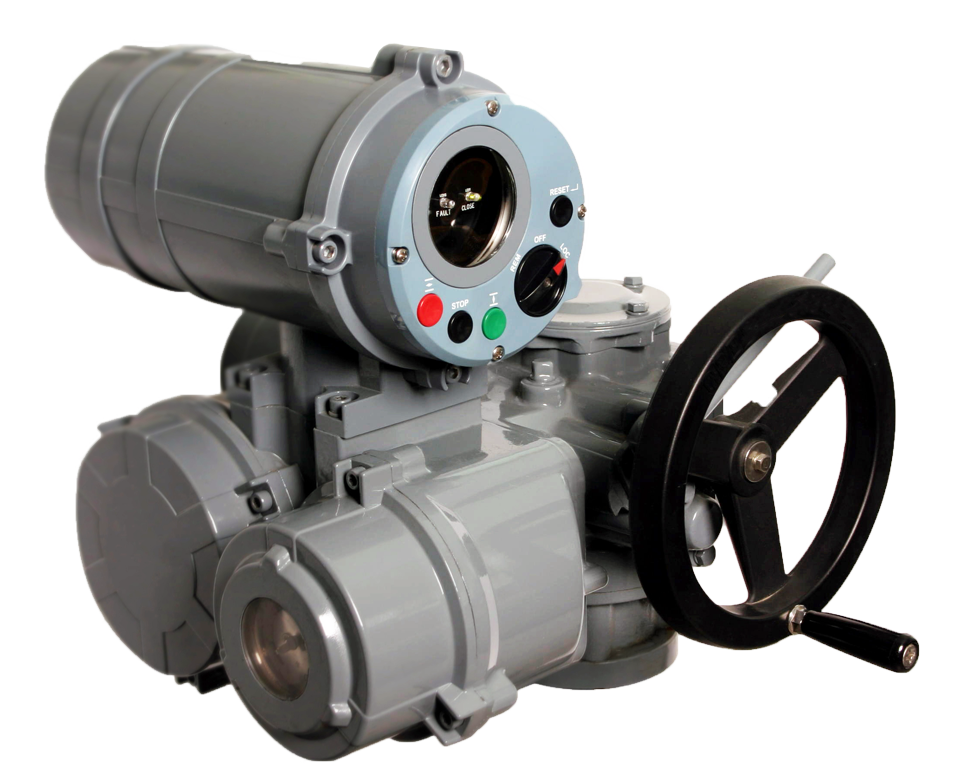

UTM Series Multi-Turn Electric Actuators

Field Proven Performance

UniTorq electric actuators offer the unique combination of a compact, efficient design utilizing proven electric actuator mechanics and the latest technological enhancements. Available in quarter-turn or multi-turn configurations, these units are ideal for applications requiring different ranges of operating torque, operation times, and size configurations. Control applications can be on/off or modulating with digital microprocessor control.

UniTorq electric actuators are being used in a large number of applications including oil and gas refining, power generation, chemical manufacturing, pulp and paper manufacturing, food and beverage processing and water treatment.

UTM Series Multi-Turn Electric Actuators

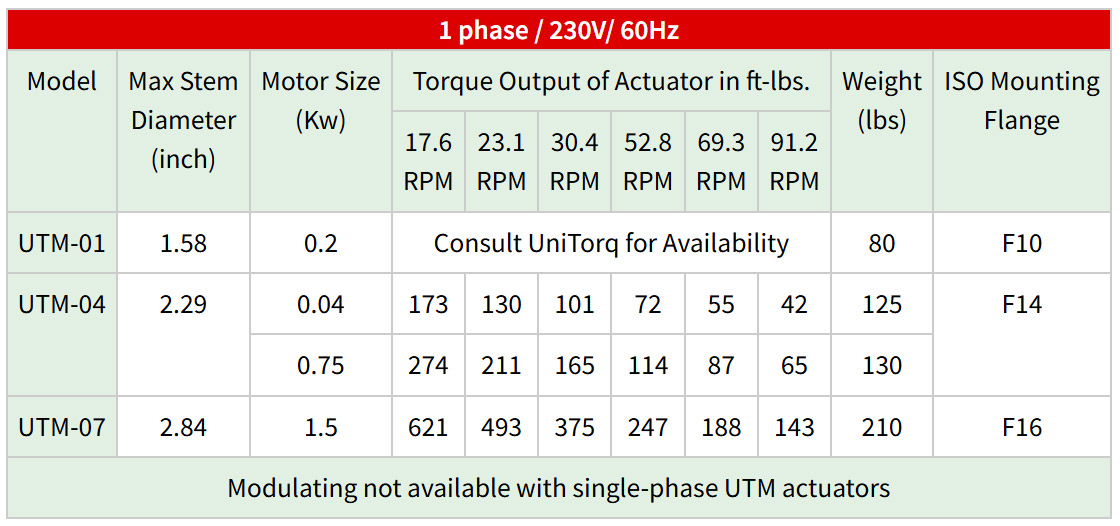

The UTM series multi-turn electric actuator provides safe, reliable, proven performance for use in industrial valve applications. With torque offerings up to 405,000 ft-lbs of torque and thrust ratings up to 1.2 million lbs. Available in single phase 220v or three phase 230/460v power, the affordable UniTorq UTM series is an ideal solution for your valve automation needs.

Features

- Durable, compact, corrosion resistant powder coated aluminum housing

- Manual operation through side mount handwheel with automatic declutch lever

- High torque/low inertia motor with embedded thermostat, Class F insulation

- Detachable thrust base, with copper alloy drive bushing

- 4 limit switches for open and closed position indication

- 2 torque switches for open and closed directions

- Anti-condensation space heater – thermistor type

- IP68 enclosure: submersible to 25′ for 72 hours

- Sealed worm gear case, EP lithium type grease lubricant (MIL-23827B)

- Meets AWWA requirements for electric motors

Options

- Integral controls

- Modulating controls

- Explosion proof Class 1 / Group C&D / Div. 1 models available

- Quarter-turn and bevel gear operators available

- Communication protocols

Marketing Literature

Engineering Documents

The links below will provide a PDF document containing dimensional drawings, weights, mounting patterns, and sizes for that model. Contact UniTorq (see form below) for wiring diagrams or additional information.